Engineering Excellence

Precision you can engineer around

Precision you can engineer around

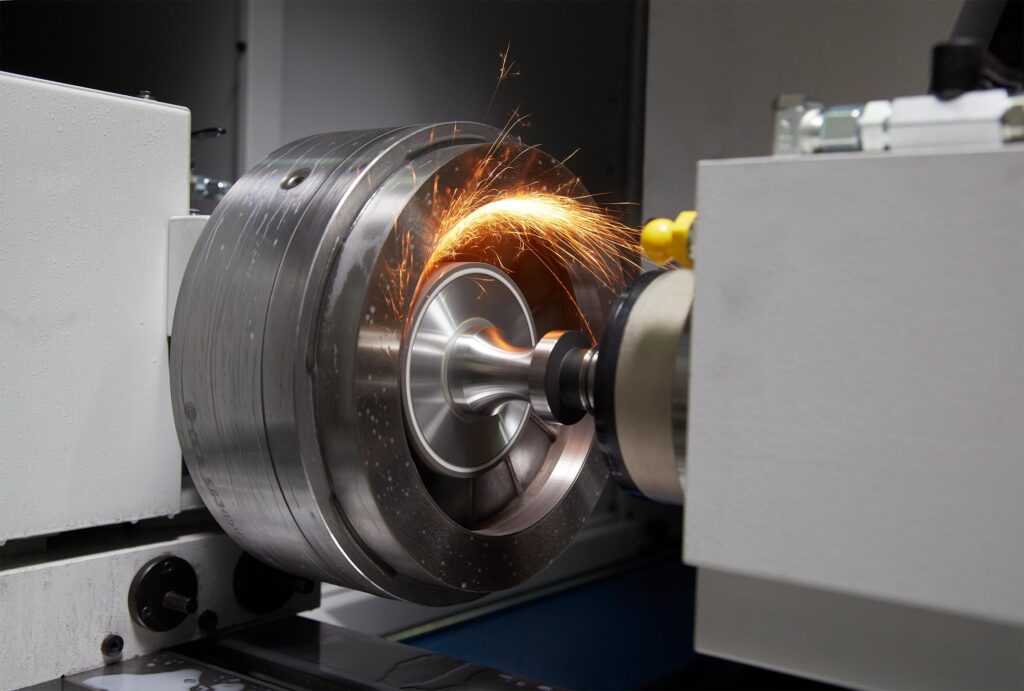

We provide high-precision machining and

engineering for projects of any scale.

Our Core Services

We keep it simple, fast, and done right.

CNC Turning

High-precision, repetitive, and complex machining

❖ Up to 12" Turning Diameter

❖ Up to 20" Turning Length

❖ Stainless Steel, Aluminum, Brass & Copper

❖ Tolerance

CNC Milling

High-precision, repetitive, and complex machining

❖ Up to 12" Turning Diameter

❖ Up to 20" Turning Length

❖ Stainless Steel, Aluminum, Brass & Copper

❖ Tolerance

Automated Saw Cutting

High-precision, repetitive, and complex machining

❖ Up to 12" Turning Diameter

❖ Up to 20" Turning Length

❖ Stainless Steel, Aluminum, Brass & Copper

❖ Tolerance

Cylindrical Grinding

High-accuracy OD grinding for precision rotational components

❖ Up to 8" Diameter

❖ Up to 24" Length

❖ Tool Steel, High Speed Steel, Cast Iron & Tool Steel

❖ Surface Finish achievable up to 0.2 Ra

Why Engineers Choose Us

Fast, precise, and reliable — from prototype to production.

Rapid Turnaround

Quick prototypes and production runs to keep projects on schedule.

Aerospace-Grade Precision

Tight tolerances ensure every part meets demanding specifications.

Collaborative Expertise

Engineers and supply chain guidance to streamline your project.

Quality & Compliance

ISO 9001-compliant inspection, documentation, and consistent results.

FAQs

1. Can you machine exotic or extremely hard materials like Tool Steel or Titanium?

A: Yes. We use our CNC Machining Centers for high-precision milling, and for materials too hard for conventional cutting, we use our specialized EDM (Electrical Discharge Machining) unit.

2. Do you offer services for large-scale metal fabrication and stock cutting?

A: Yes. We use our Horizontal Band Saw for efficient, high-volume cutting of large-diameter bar stock and tubing, ensuring precise and square material preparation for subsequent machining or fabrication.

3. What file formats do you accept for CNC Machining jobs?

A: We primarily accept standard industrial formats, including STEP, IGES, DXF, and traditional 2D mechanical drawings (PDF/DWG). Our programmers use these files to generate the code for our Mitsubishi and FANUC control systems.

4. What is your typical lead time for small-batch custom components?

A: Lead times vary based on material availability and machine scheduling. However, using our versatile Conventional Lathe and Milling Machine, we can often prioritize small, urgent custom or repair components for faster turnaround than high-volume CNC jobs.

5. What level of accuracy can you hold with your Grinding Services?

A: Our Cylindrical Grinding Machine is capable of achieving extremely tight dimensional tolerances and superior surface finishes, typically down to Ra 0.2 μm (8 microinches), essential for bearing fits, sealing surfaces, and critical shafts.

Let's get started right away

Fast quotes. High-precision execution. Quality guaranteed.